Hanlar Machines

HANLAR MAKINE was established in 2005 as a small entreprenourship for the purpose of producing filling machines, capping machines, labeling machines in Istanbul.

HANLAR MAKINE is currently one of the most successful Turkish manufacturers and suppliers of packaging machines.

HANLAR MAKINE offers a wide range of high quality products which are also specifically designed to meet the customer needs for high flexible applications.

HANLAR MAKINE is effectively providing all sales and after sales related services not only in Turkey and North Africa, Middle East, East Europe, CIS countries but also in a wide range of geographical areas including Turkish countries and Middle Africa.

In parallel to the growing and developing industry as a result of today’s conditions, we are growing together with our customers and suppliers, and we are increasing our co-operation with new suppliers whenever necessary to provide good products to our customers.

Machines

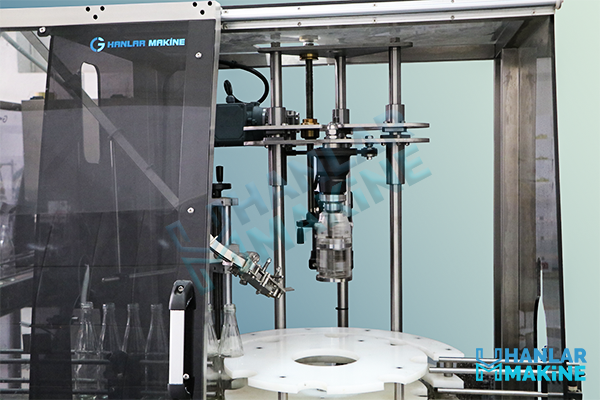

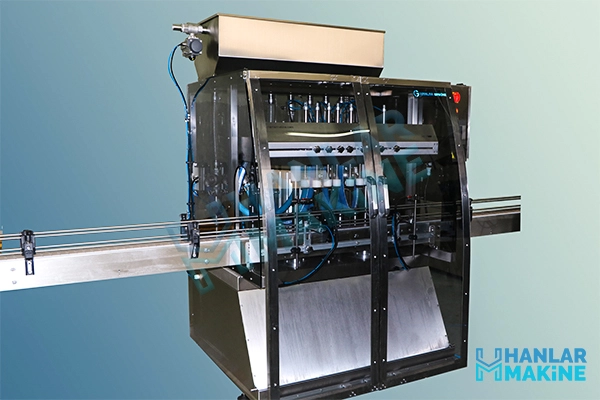

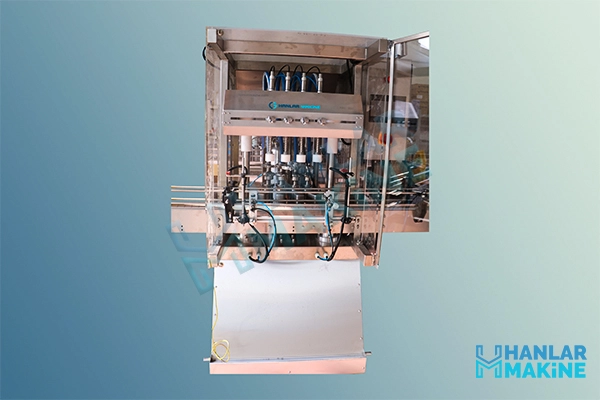

Piston Filling Machine - HMP/3000

.webp)

HMP 3000 Volumetric filling Machine’s Electro Pneumaticly controlled ,volumetric filling system, Electronically , product level controlled Filling Tank(hopper) mounted over the machine All adjustments can be done through PLC All the surfaces to which product touches are made of SS 316, Filling ranges from 5-50 ml ,10-000 ml,100-1000 ml,500-5000 ml ,other filling ranges are also designable as per requirement , The sealings,o rings ,etc..are designed with referance to the product’s chemical specifications , The machine is suitable for viscous products ,and semi viscous products

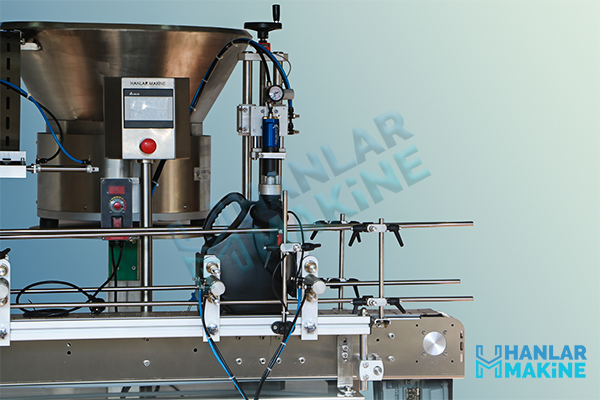

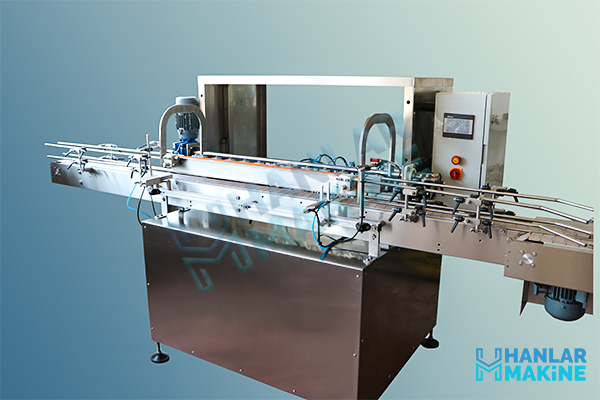

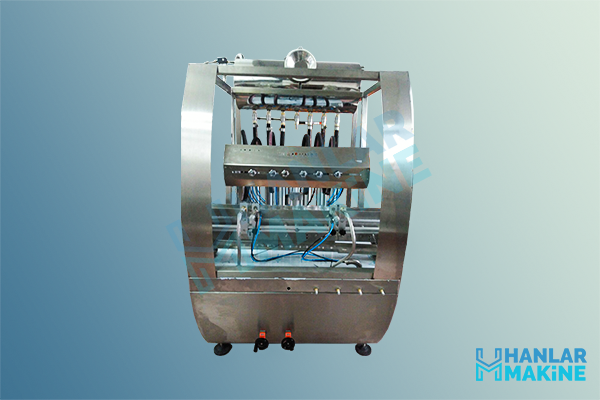

Vacuum Filling Machine-HMV/3000

HMV 3000 Vacuum filling (free flow principle) The machine works with free flow &vacuuming system, Suitable for Liquids ,Agressive liquids and foaming liquids like glass cleaner or vinegaar , All bottles are filled at the same level irresspective of the inner capacities of the bottles ,Vaccum system prevents foaming , Simple design ,easy to change from bottles to bottles ,

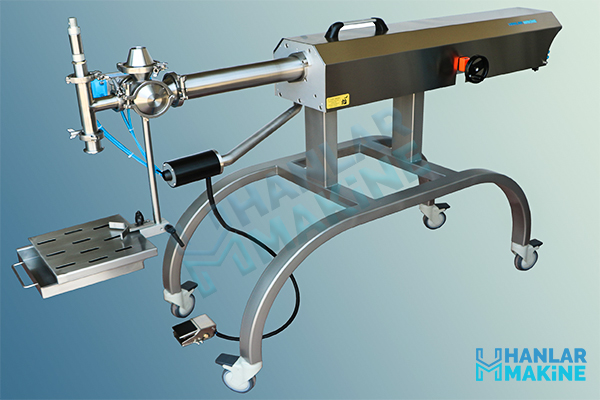

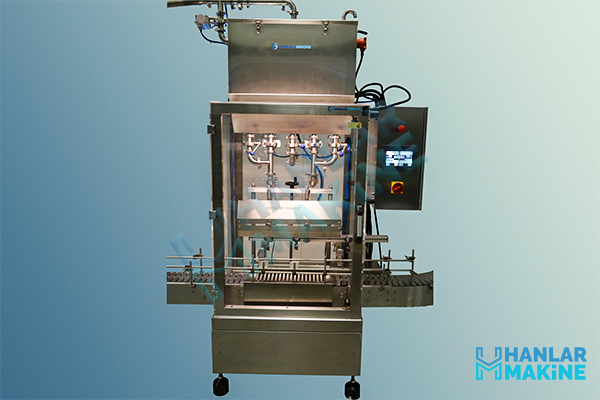

T/500-Semi Automatic Piston Filling Machine

1the volumetric filling machine is controlled by pneumatic system ,the nozzles are designed ,as per packages with anti dropping system , filling amount is adjusted and recorded via mechanic indicator , as the machine produced on wheels can be transported easily to anywhere for filling , the filling range is variable as per requirement , fort he viscous products hopper should be used

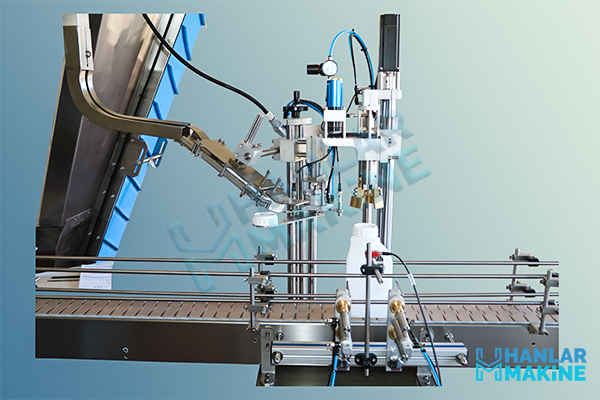

CAP/PTV-L PushPull Triger Valve Capping Machine

The machine works with 4 wheel system located on the left and wrigth side ,also have a bottle position correcting system to provide true capping ,suitable for push-pull,trigger valve type caps , Lineer or rotating systems are available ,the capacity of the machine is variable ,depending on the bottles and caps dimensions

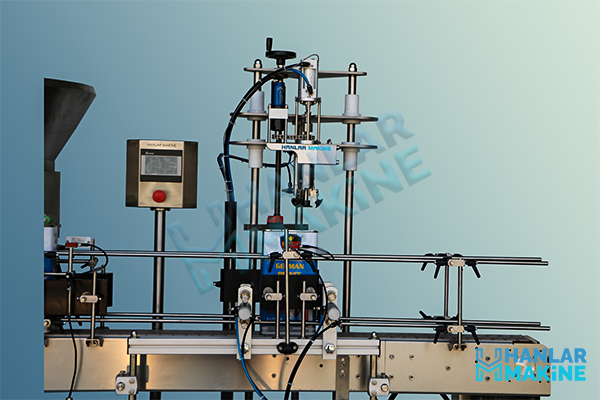

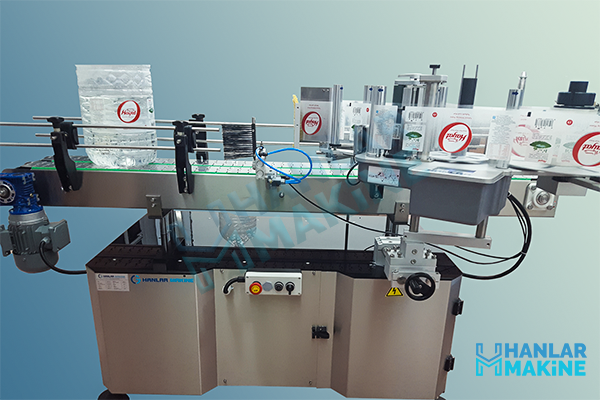

Double Side Labeling Machine

All parameters are adjustable via buttons on the micro processor,like label length adjustment , Label positioning etc,, For the konical bottles ;the label angles adjustment system is standart on all the machines The chasis are made of AISI 304 SS , easy mounting and compact design competetive prices

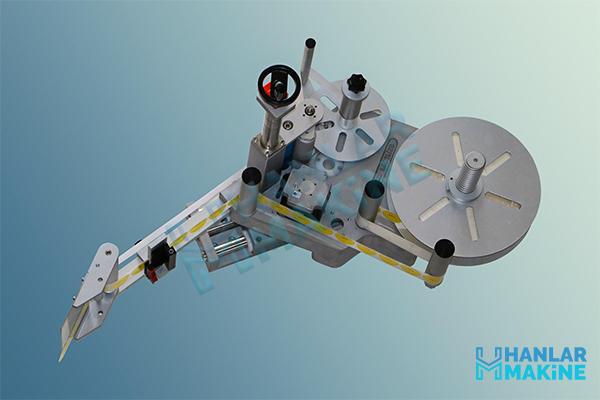

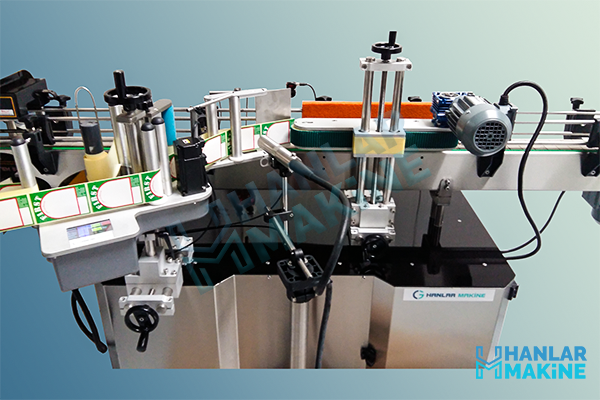

EMT/300- One Side Labeling

Machine

All parameters are adjustable via buttons on the micro processor,like label length adjustment , Label positioning etc,, For the konical bottles ;the label angles adjustment system is standart on all the machines The chasis are made of AISI 304 SS , easy mounting and compact design competetive prices

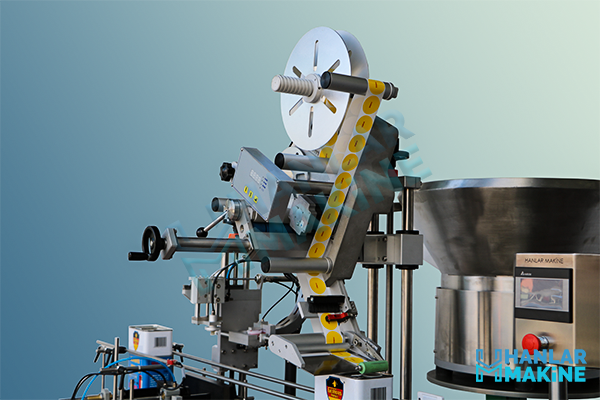

EMY/200 - Round Bottle Labeling Machine

All parameters are adjustable via buttons on the micro processor,like label length adjustment , Label positioning etc,, For the konical bottles ;the label angles adjustment system is standart on all the machines The chasis are made of AISI 304 SS , easy mounting and compact design competetive prices

EMD/100 - Vertical Labeling Machine

All parameters are adjustable via buttons on the micro processor,like label length adjustment , Label positioning etc,, For the konical bottles ;the label angles adjustment system is standart on all the machines The chasis are made of AISI 304 SS , easy mounting and compact design competetive prices

You Can Contact Us

You can ask questions that you are wondering by communicating with us.

Address

Balibey Mah.Ağva Cad.Tamirhane Sk. D Blok, No.19, Şile, Istanbul, TürkiyeTelephone

+90 216 739 5526GSM

+90 507 142 7303+90 536 383 1179

.jpg)